What is Covering or Lap Length in RCC?

Because of the constrained length of the bar, lapping of bars are required in an individual from more than 12m long or where the length of bar required is more than 12m.

Lap Length:- Covering Length or Lap Length is given to keeping up the congruity of bars so as to securely move the heap starting with one bar then onto the next bar. It relies upon the Evaluation of Cement, the evaluation of steel and dia. of the bar.

The amount Lap Length is Given in Section?

According to IS Code 456-2000 covering length ought not be under 75mm. Lapping ought to be kept away from in the tractable zone of development individuals. If there should be an occurrence of segment by and large, we take 24d – 40d where 'd' is dia of the bar.

Significant Point Ought to be Recall for Segment Lap Length:

1-Lapping ought to be given at the focal point of the segment since bowing minute at the midpoint is zero so attempt to lap at the midpoint.

2-Lapping of bars ought to be given then again. Lap ought not be given at same point on the grounds that clasping may happen.

3-Horizontal ties ought to be given firmly divided in Lapping zone.

4-Because of most extreme pressure, we can't lap at the section/shaft/piece joint. Lapping ought not be given at L/4 good ways from top and base of the piece.

The amount Lap Length is Given in Shaft?

If there should arise an occurrence of the pillar we by and large utilize 24d for pressure zone and 45d for elastic/strain zone.

Significant Point Ought to be Recall for Pillar Lap Length:

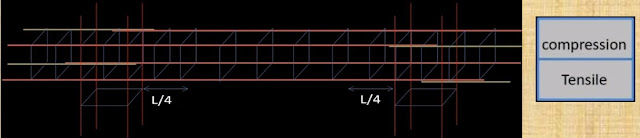

1-Lapping (24d) in top bars stayed away from L/3 good ways from the two finishes. For top bar, lapping ought to be at mid-length.

2-Lapping (45d) in base bars lap ought to be given at segment intersection or L/4 good ways from segment face however ought not be in mid-range of the pillar.

3-Stirrups ought to be firmly dispersed close to the sections and lose/ordinary at mid-length.

4-Lapping of bars ought to be on the other hand given.

The amount Lap Length is Given in Piece?

On account of the piece, we use lap length 50d where 'd' is dia of the bar.

Significant Point Ought to be Recollect for Piece Lap Length:

1-RCC chunks work is like shafts if the piece is planned as one way. It is perfect to lap bars at purpose of the least twisting minute or at purposes of contra flexure.

2-For all intents and purposes laps are given past L/5 to L/3 ( L being the compelling range) from help for bars at base of the chunk. The top bars are commonly short and no laps are important. Be that as it may, at no time, the lapped bars will surpass 33% of the absolute bars.

3-Bars will be considered stunned if a start to finish separation b/w laps is at any rate (lap length +75mm)

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment